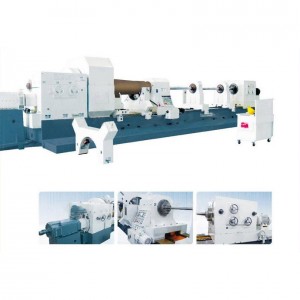

Pengeboran silinder lan mesin boring, Pengeboran Lubang Jero lan Mesin Boring Seri T2150/T2250

Tampilan Video

Deskripsi Fungsi

Mesin cocok kanggo ngebur, mboseni, rolling lan trepanning Processing ing Manufaktur mesin, lokomotif, kapal, mesin batu bara, silinder hydraulic, mesin daya, mesin pneumatik lan industri liyane, supaya roughness lumahing workpiece tekan 0,4-0,8 μm.Seri mesin mboseni bolongan jero iki bisa milih formulir kerja ing ngisor iki miturut kahanan benda kerja:

1. Rotasi workpiece, rotasi alat nglereni lan gerakan feed reciprocating.

2. Workpiece muter lan alat nglereni ora muter, iku mung ndadekake gerakan feed reciprocating.

3. Workpiece ora muter;alat nglereni muter lan reciprocates.

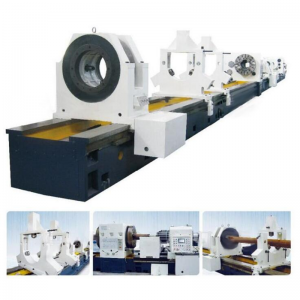

Parameter teknis

| Jinis | T2150 | T2250 | T2150/1 | T2250/1 | |||

| Kapasitas | Pangolahan Dia.kisaran (mm) | Pengeboran Dia.Pengeboran Dia. | Φ40~Φ120 |

| Φ40~Φ120 |

| |

| Boring Dia. | Φ40~Φ500 | ||||||

| Trepanning Dia. | Φ50~Φ250 | ||||||

| Kisaran OD saka benda kerja (mm)Workpiece njaba Dia. | Φ100~Φ670 | ||||||

| Kedalaman pengeboran/boring/trepanning (mm) | 1m~16m | ||||||

| nindakake -anjeng | Z sumbu | Kacepetan pakan (mm/min) | 5~2000 | ||||

| Kacepetan lelungan cepet (m/min) | 2000 | ||||||

| Torsi motor feed (Nm) | 49 | 49 | 49 | 49 | |||

| Kepala lelungan kanthi bar pengeboran puteran | Maks.kacepetan puteran r/min) |

|

| 500 | 500 | ||

| Daya Motor (AC asinkron) |

|

| 30 | 30 | |||

| Headstock | Maks.kacepetan puteran (r/min) | 315 | |||||

| Daya Motor (KW) | 37 | ||||||

| Sistem coolant | Maks.tekanan (MPa) | 2.5 | 0.63 | 2.5 | 0.63 | ||

| Maks.aliran (L / min) | 800 | 800 | 800 | 800 | |||

| liyane | Maks.rasio ambane ngebur lan Dia. | 100:1 | |||||

| Daya Umum (Kw.) | 65 | 30 | 65 | 65 | |||

Swara Dimensi lan Bobot

| dawa | Spasi aliran (L × W) mm | Bobot Net (T) | dawa | Spasi aliran (L × W) mm | Bobot Net (T) |

| 1000mm | 9500×3800 | 18 | 7000 mm | 23500×3800 | 39 |

| 2000 mm | 11500×3800 | 21 | 8000 mm | 25500×3800 | 43 |

| 3000 mm | 13500×3800 | 24 | 9000 mm | 27500×3800 | 47 |

| 4000 mm | 15500×3800 | 27 | 10000mm | 31500×3800 | 51 |

| 5000mm | 17500×3800 | 31 | 11000 mm | 33500×3800 | 55 |

| 6000 mm | 19500×3800 | 35 | 12000 mm | 35500×3800 | 59 |